Electric actuators rely on electric power to operate. The motor drives a gear system that reduces speed and increases torque, turning a rotating screw. This screw then interacts with the nut on the other end, causing linear motion. By controlling the forward and reverse rotation of the motor, the actuator is able to complete repetitive linear movements. On the other hand, hydraulic actuators use the pressure generated by a hydraulic pump to drive fluid, enabling them to perform complex motions.

1. Advantages and Disadvantages of Hydraulic Actuators

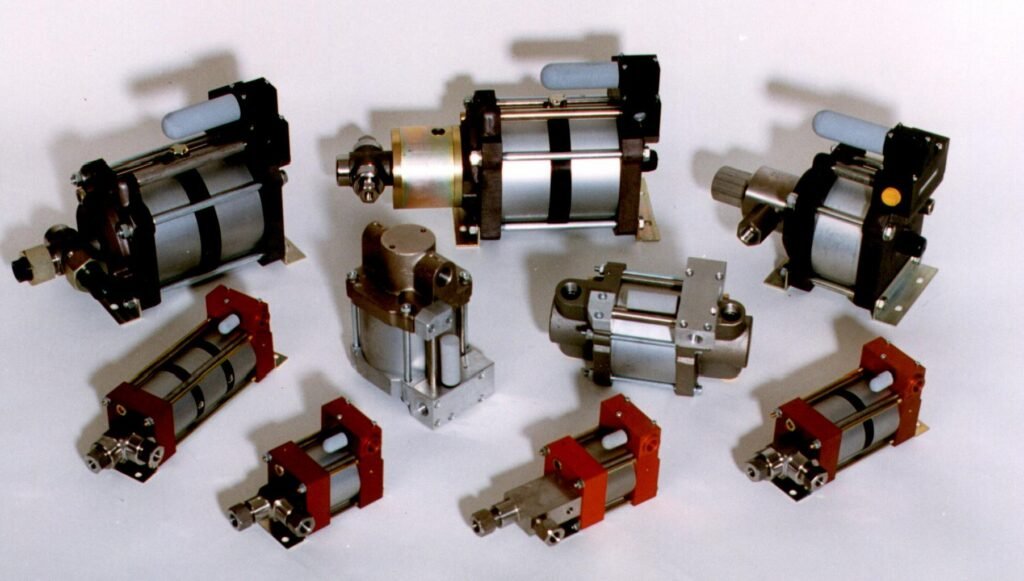

Hydraulic systems have several significant advantages, such as rapid speed and powerful torque. They offer high driving force, can handle high-pulse loads, and are ideal for heavy or uneven loads. However, there are some drawbacks to hydraulic systems. Their design is relatively complex, and choosing the right components can be challenging. The structure is intricate, making planning and layout difficult. Hydraulic systems are prone to leaks, and maintenance can be time-consuming and labor-intensive. They are sensitive to temperature fluctuations, have weak resistance to environmental pollution, and have lower safety performance, potentially posing a threat to personnel. Additionally, maintenance costs are higher due to the need for regular servicing and replacement of wear parts. The efficiency tends to be lower, and they lack precise control over transmission ratios, with limited scalability and weak capabilities for intelligent control.

2. Advantages and Disadvantages of Electric Actuators

Electric actuators offer many advantages. In terms of health and safety, they provide a more compact, quiet, and cleaner design, significantly reducing the safety risks associated with hydraulic systems. In terms of controllability, electric actuators offer precise positioning, multi-axis synchronization, and a wide range of feedback options, enhancing machine productivity and efficiency. They also simplify engineering designs by reducing the number of components, which lowers overall costs and installation time. Electric actuators, like the THOMSON Electrak® HD, use innovative modular control concepts, allowing users to select various configurations based on their needs. From an energy efficiency perspective, electric actuators are highly efficient, driving loads with lower total power usage while maintaining excellent energy efficiency. Additionally, they can operate stably in harsh environments with low noise and no leakage.