-

Electro-Hydraulic Actuators: Features, Issues, and Comparisons

2025-08-22Electro-hydraulic actuators are highly capable and can meet most of the goals of electro-hydraulic servo actuators. While motor-driven electro-hydraulic actuators have plenty of advantages, they fall short when it comes to handling high power, long strokes, heavy inertia, and complex compensation needs—areas where traditional electro-hydraulic servo actuators really shine. Compared with pneumatic actuators, electro-hydraulic actuato...

-

What fields are electro-hydraulic actuators used in?

2025-08-19Electrohydraulic actuators are a crucial component of automatic control systems. Their function is to receive control signals from a controller and alter the pressure of the controlled medium to maintain the controlled variable at a desired value or within a certain range. Actuators can be categorized into three types based on their energy source: pneumatic, hydraulic, and electric. Pneumatic actuators use compressed air as their ene...

-

Electro-Hydraulic Actuator Technology: Comparison and Troubleshooting Analysis

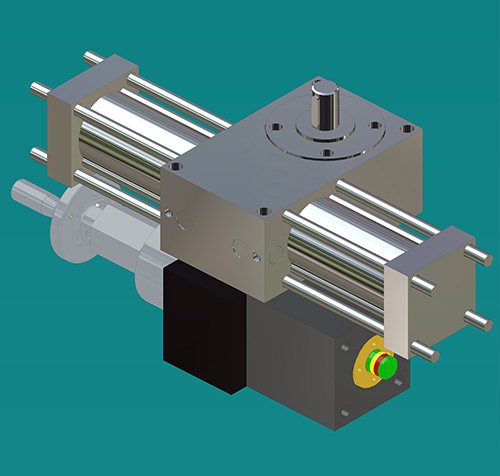

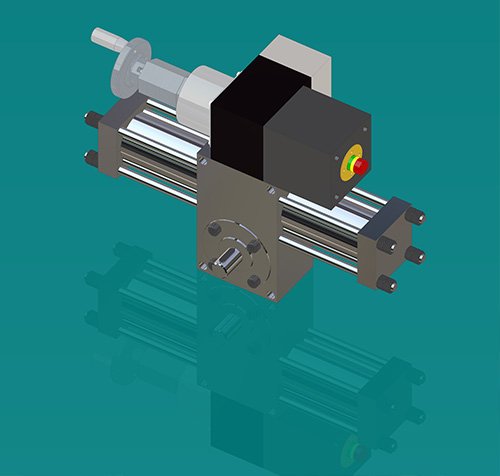

2025-08-14Motor-Controlled Electro-Hydraulic Actuators Manufacturers of motor-controlled electro-hydraulic actuators employ closed-loop hydraulic systems that utilize stepper or servo motors to regulate the direction and flow of pressure oil from bi-directional pumps. This design enables precise control of controlled objects, as exemplified by industry leaders like REXA (USA). Performance Advantages and Limitati...

-

Electric Actuators vs. Electro-Hydraulic Actuators: A Comprehensive Overview

2025-08-14Electric actuators, also known as electric execution arrangements, are widely used in industries where precise control of motion is necessary. These actuators use single-phase or three-phase motors to drive gears or worm gears to provide linear or rotary motion. Electric actuators are known for their ability to output a relatively constant driving force, offering high stability and strong resistance to errors. They also provide highe...

-

Essential Hydraulic System Maintenance Tips to Extend Service Life

2025-08-14Proper maintenance of your hydraulic power unit is crucial. Neglecting daily care will gradually reduce performance and shorten the lifespan of the hydraulic system. Here are the key steps to keep your system running smoothly and efficiently. 1. Keep Hydraulic Oil Clean Hydraulic oil plays a critical role in system performance. It not only lubricates moving parts and prevents rust but also absorbs and transfers heat, prot...

-

Composition principle and application of electro-hydraulic actuator

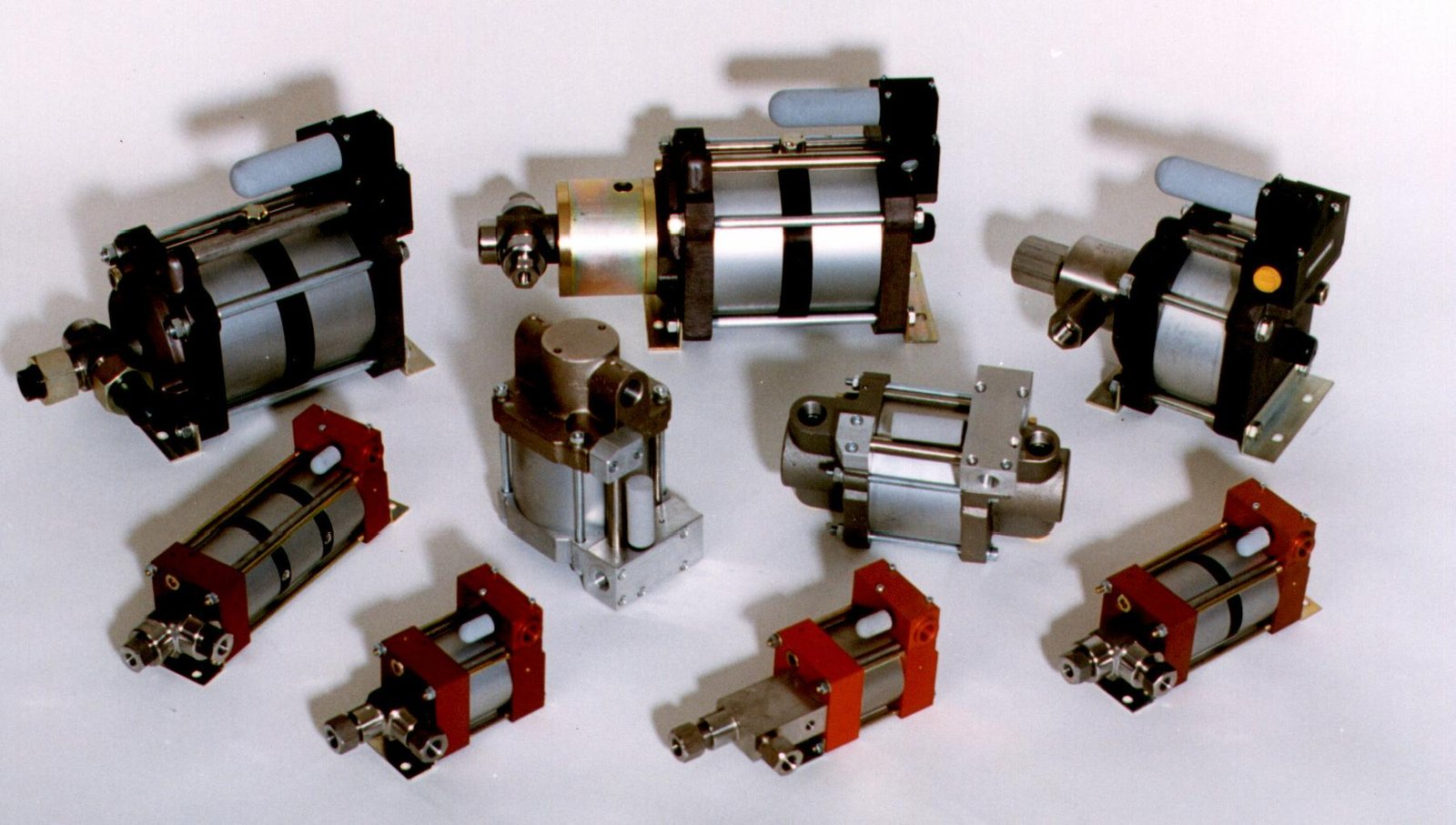

2025-08-07As a power device, actuators integrate pneumatics, hydraulics, control, electromechanical, computer, and communications technologies to precisely control the position of controlled objects quickly and stably. They are not only used to drive and control various valves, but are also widely used in numerous applications requiring power in fields such as electricity, water conservancy, metallurgy, papermaking, aerospace, pipelines, petro...

-

The difference between electro-hydraulic actuators and electric actuators

2025-08-07There are three main types of actuators used for control valves: electric, hydraulic, and electro-hydraulic. Each has its own advantages and disadvantages, which are discussed below. Actuators: Actuators are currently used in most industrial control applications. Because they are powered by gas, they are more economical than electric and hydraulic actuators. They also have a simpler structure and are easier to operate and maintain...

-

Electric vs. Hydraulic Actuators: Working Principles

2025-08-01Electric actuators rely on electric power to operate. The motor drives a gear system that reduces speed and increases torque, turning a rotating screw. This screw then interacts with the nut on the other end, causing linear motion. By controlling the forward and reverse rotation of the motor, the actuator is able to complete repetitive linear movements. On the other hand, hydraulic actuators use the pressure generated by a hydraulic ...

-

Common faults of hydraulic reversing valves

2025-07-18The only difference between a hydraulic directional valve and an electromagnetic directional valve is the force that pushes the valve core to move. The former is the hydraulic pressure of the pressure oil, and the latter is the suction force of the electromagnet. The specific fault analysis and troubleshooting methods of hydraulic directional valves are as follows. Fault: (1) No reversal or poor reversal Cause: The pressure...

-

Low speed high torque hydraulic motor

2025-07-18The shaft connecting rod type low speed and high torque motor is suitable for the hydraulic transmission system of various machinery such as mining and construction machinery, overweight transportation equipment, heavy metallurgical machinery, petroleum and coal mining machinery, ship deck machinery, machine tools, light industry, plastic machinery, geological drilling equipment, etc. It is especially suitable for the screw drive of ...