PRODUCTS

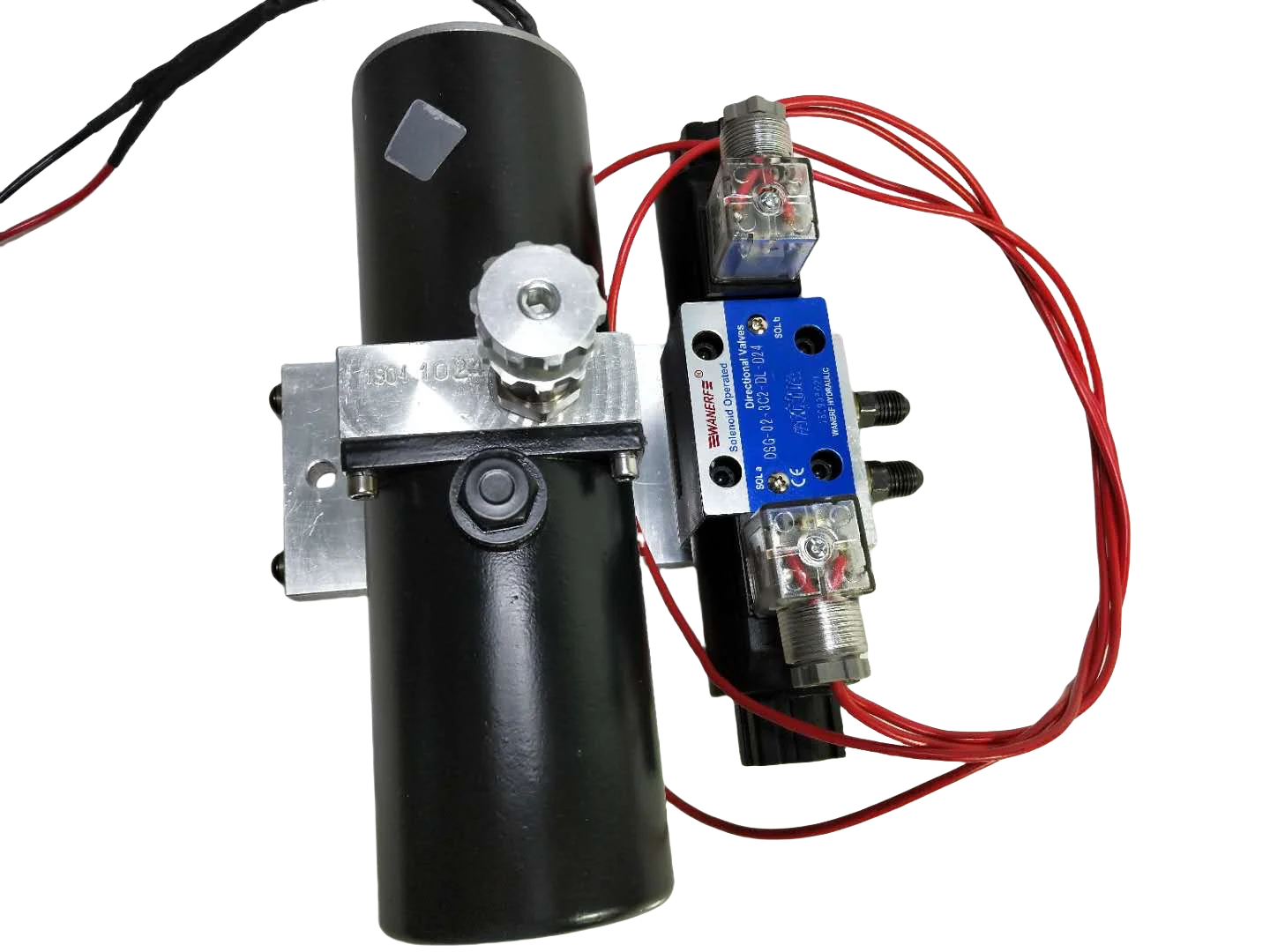

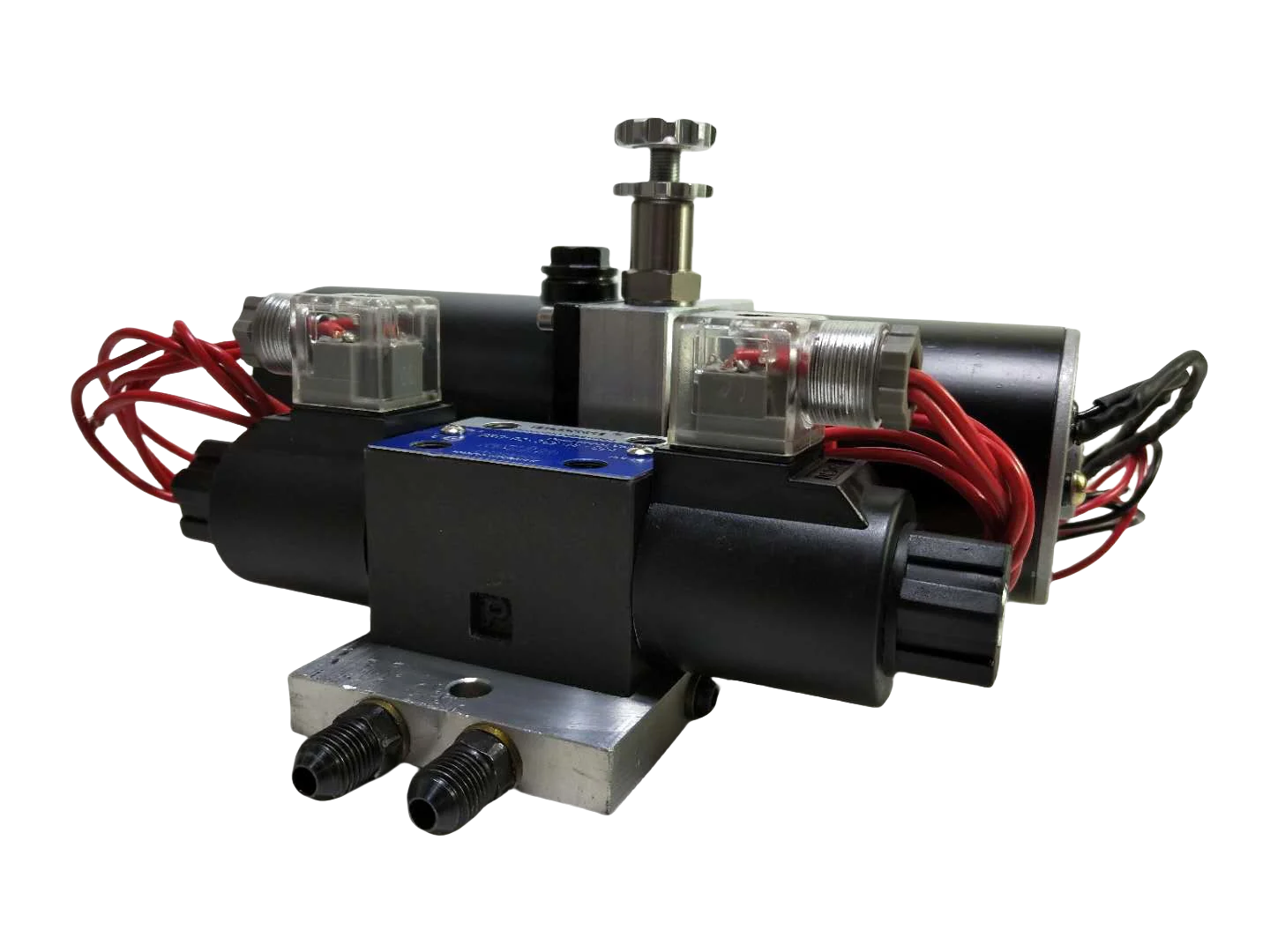

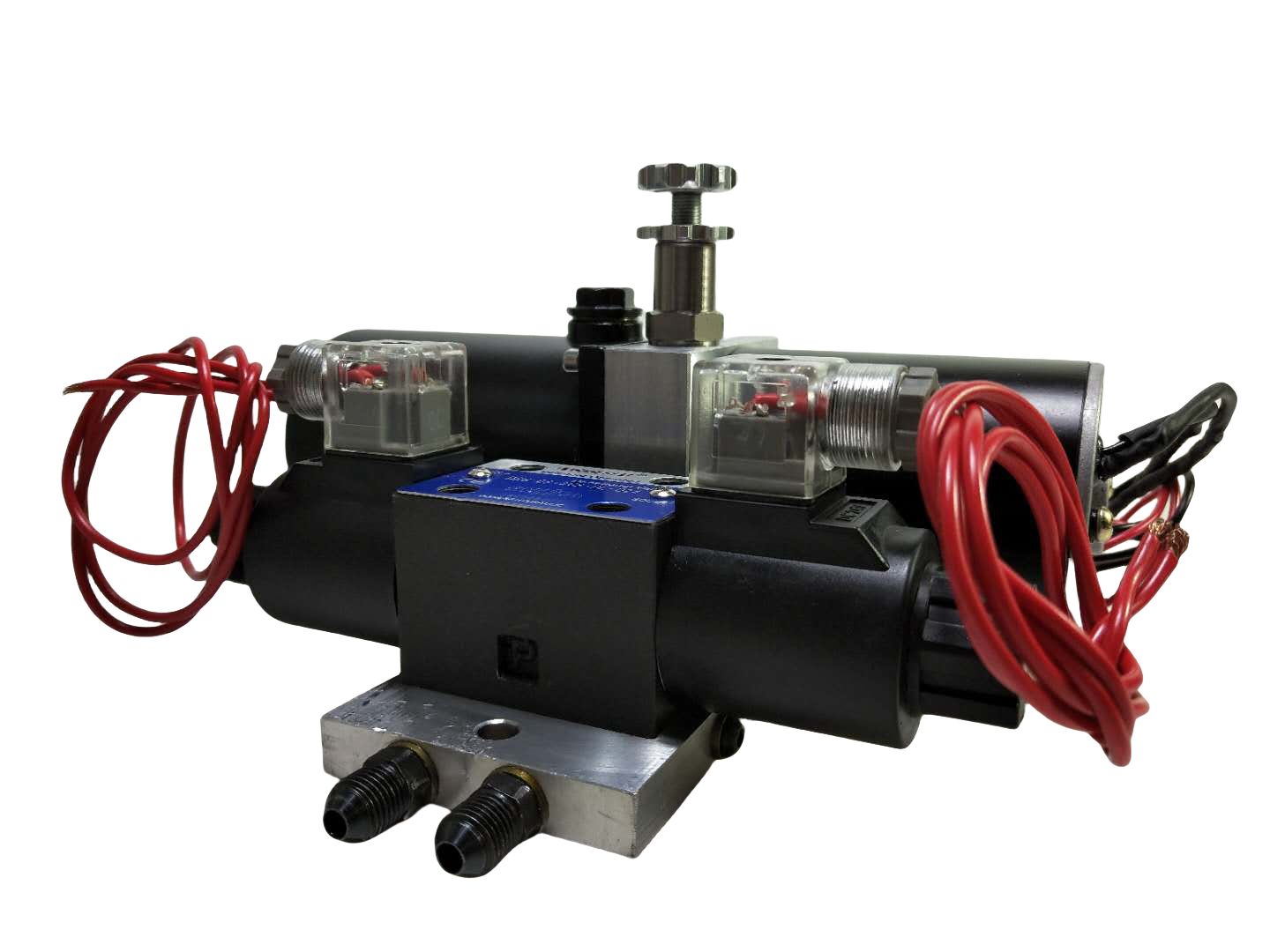

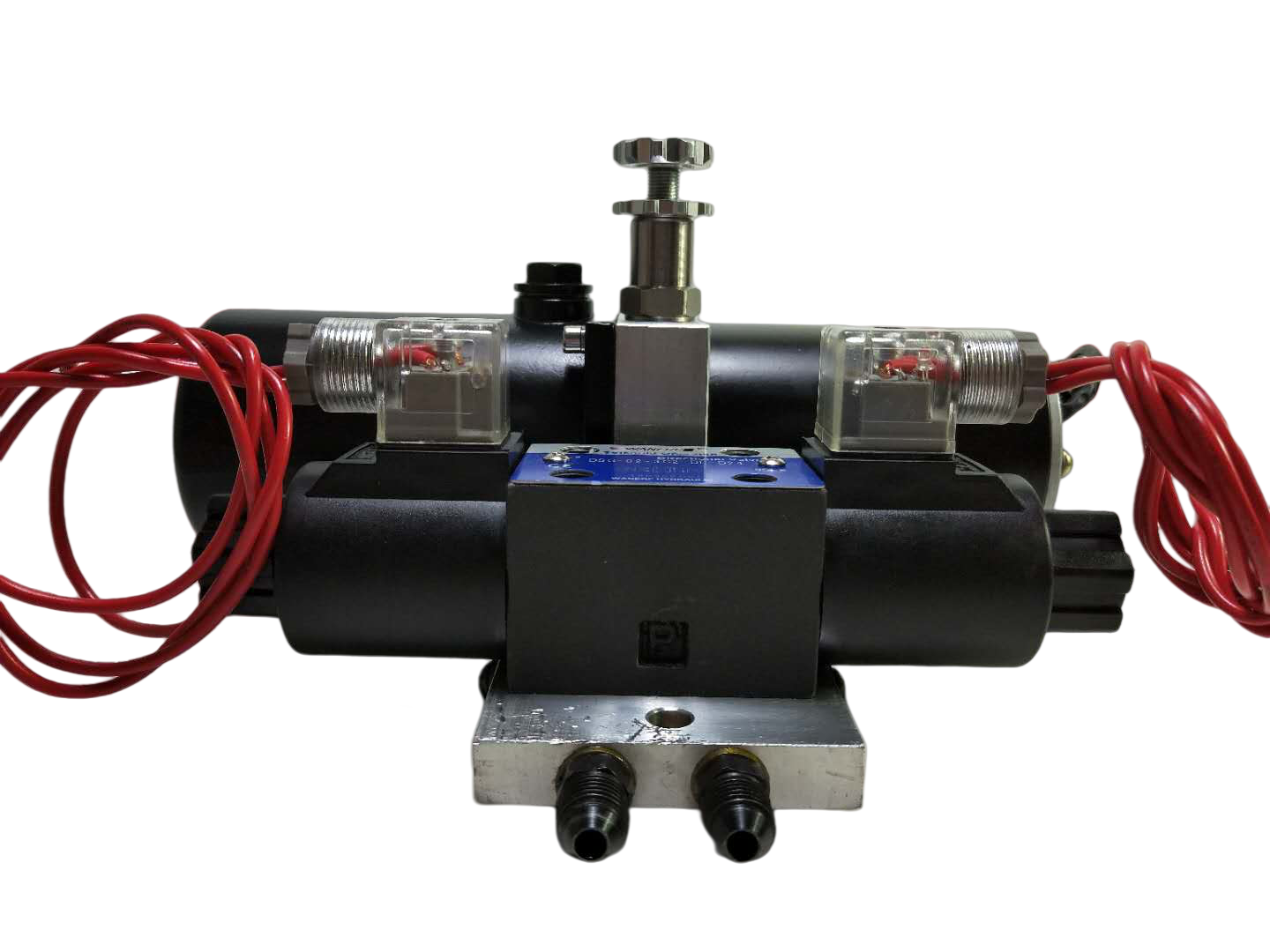

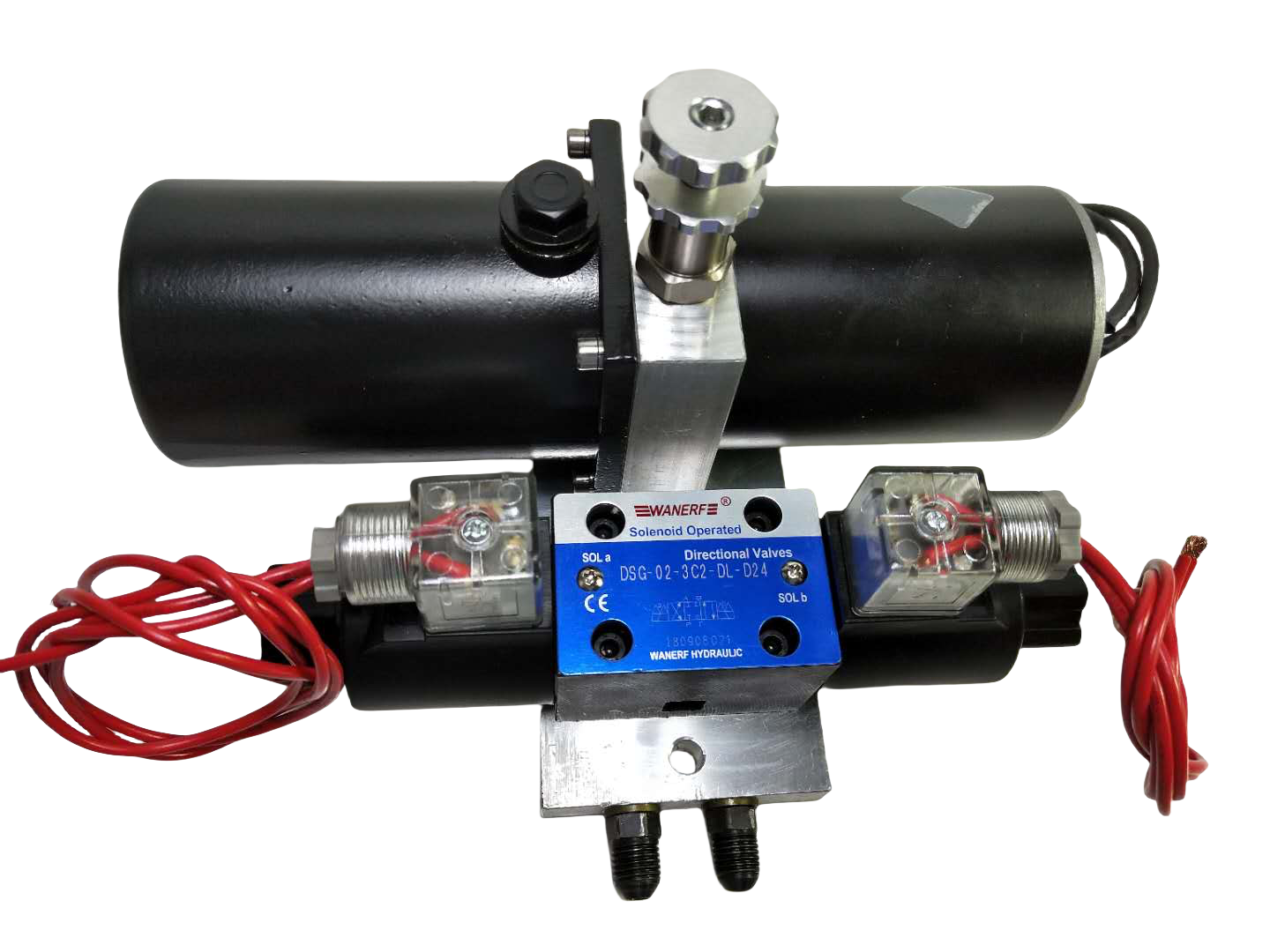

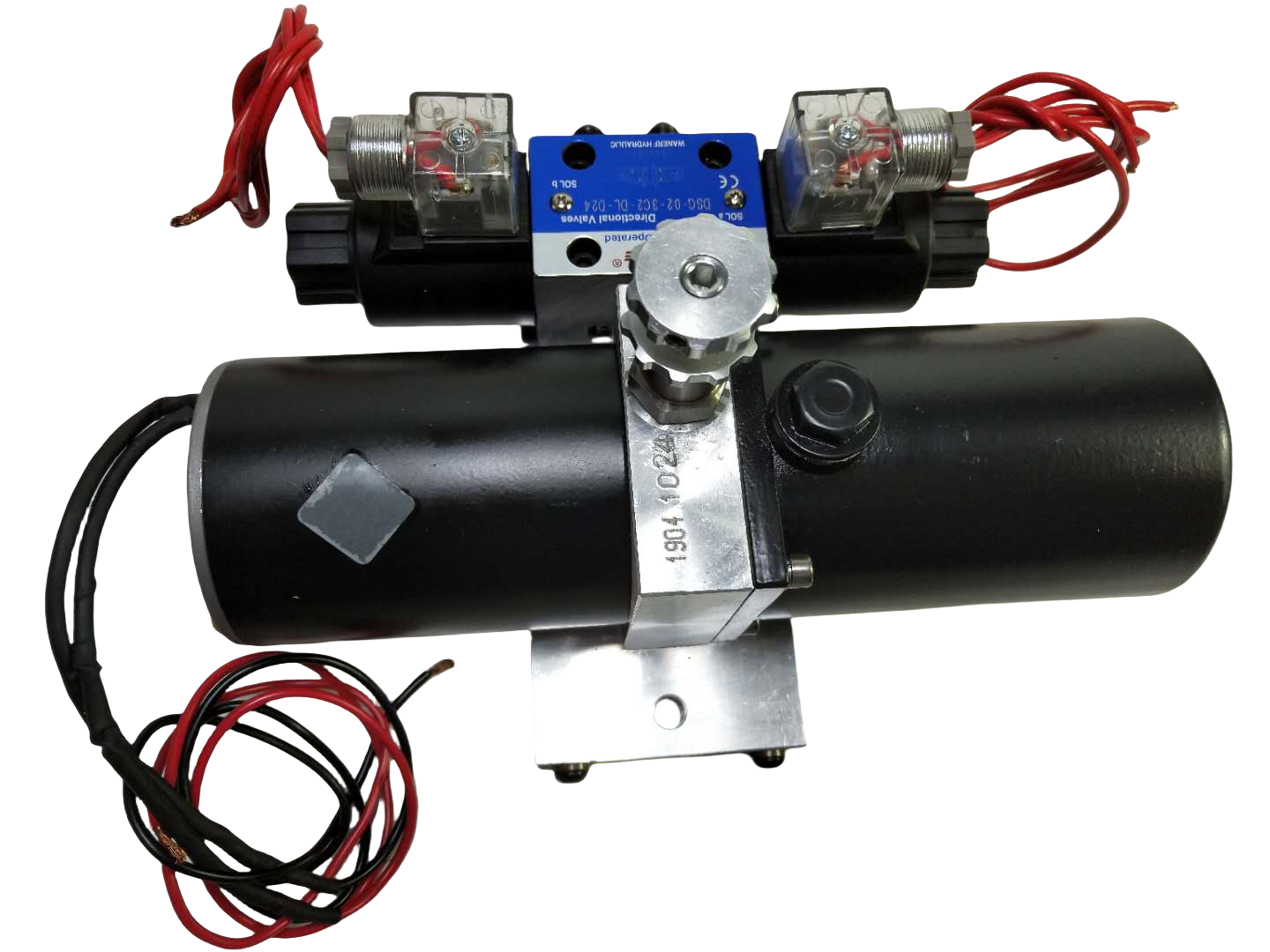

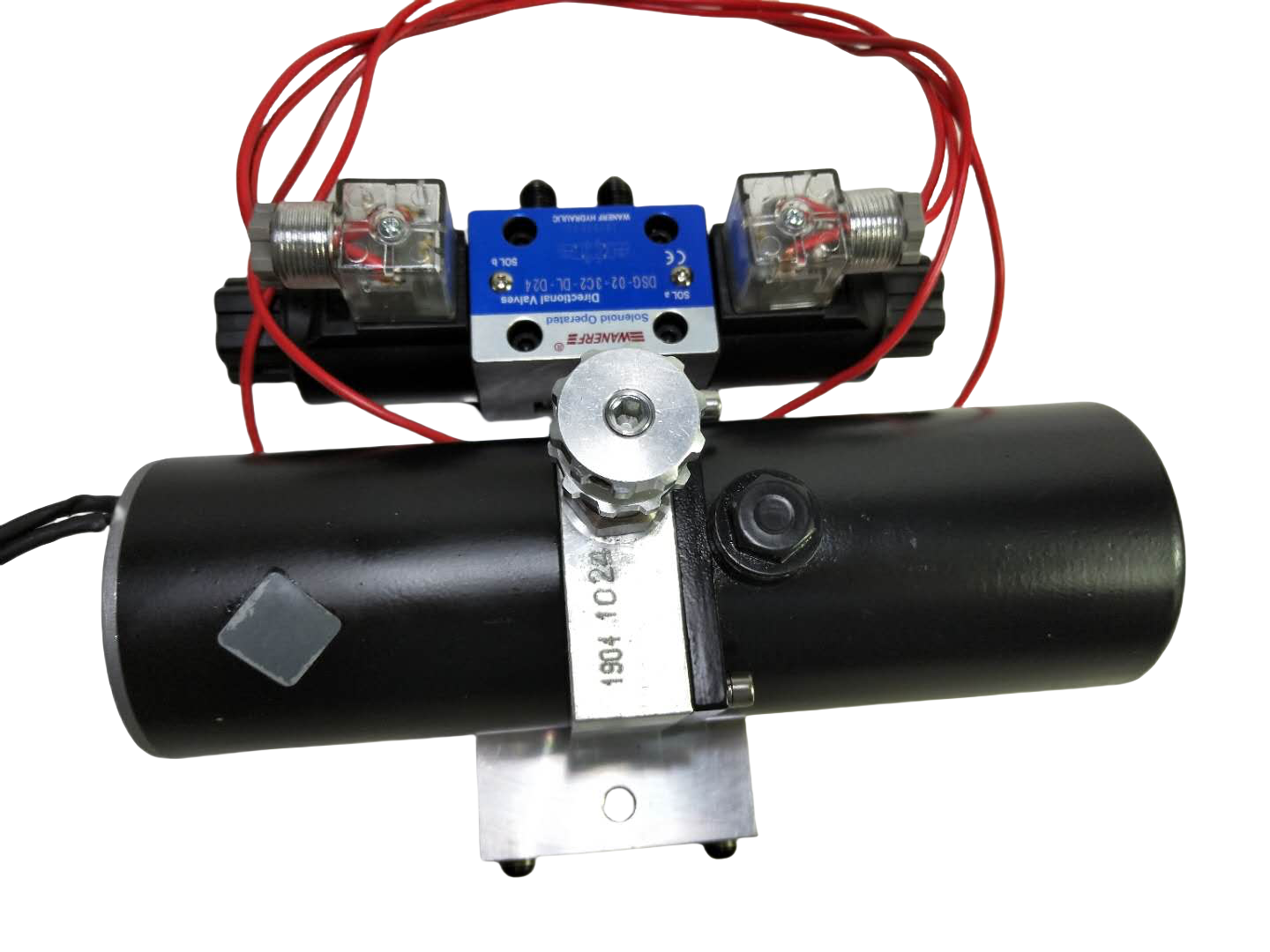

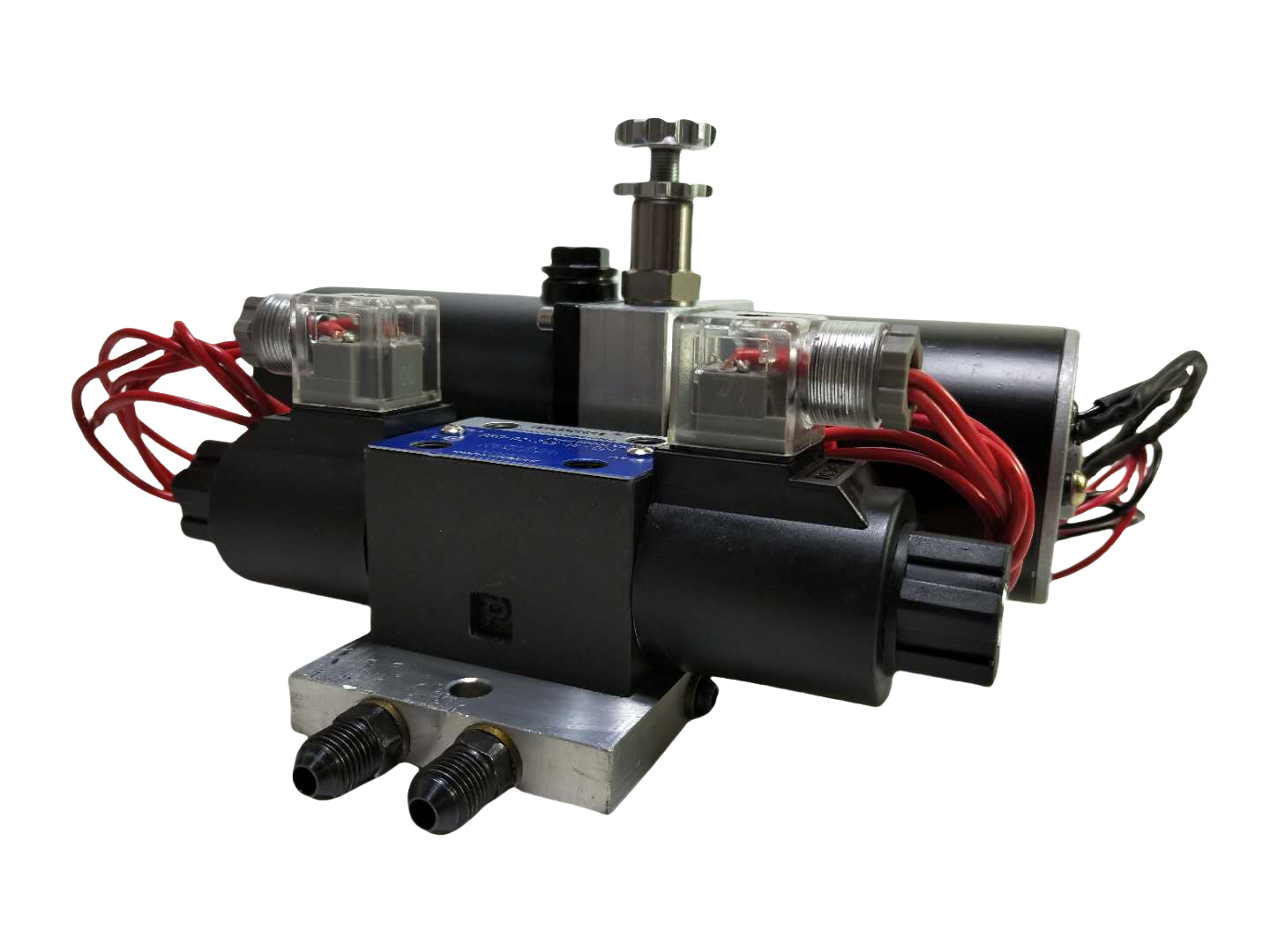

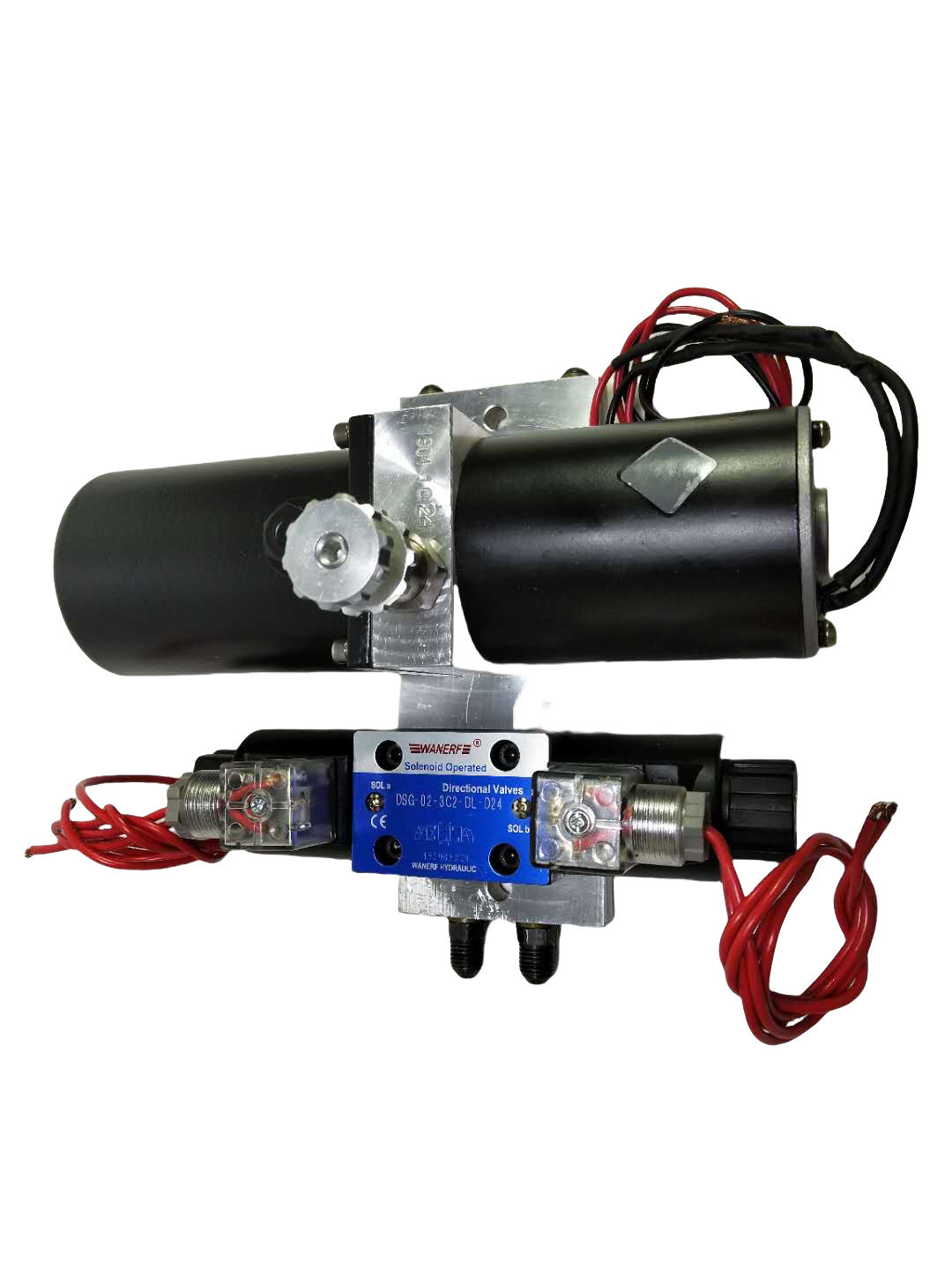

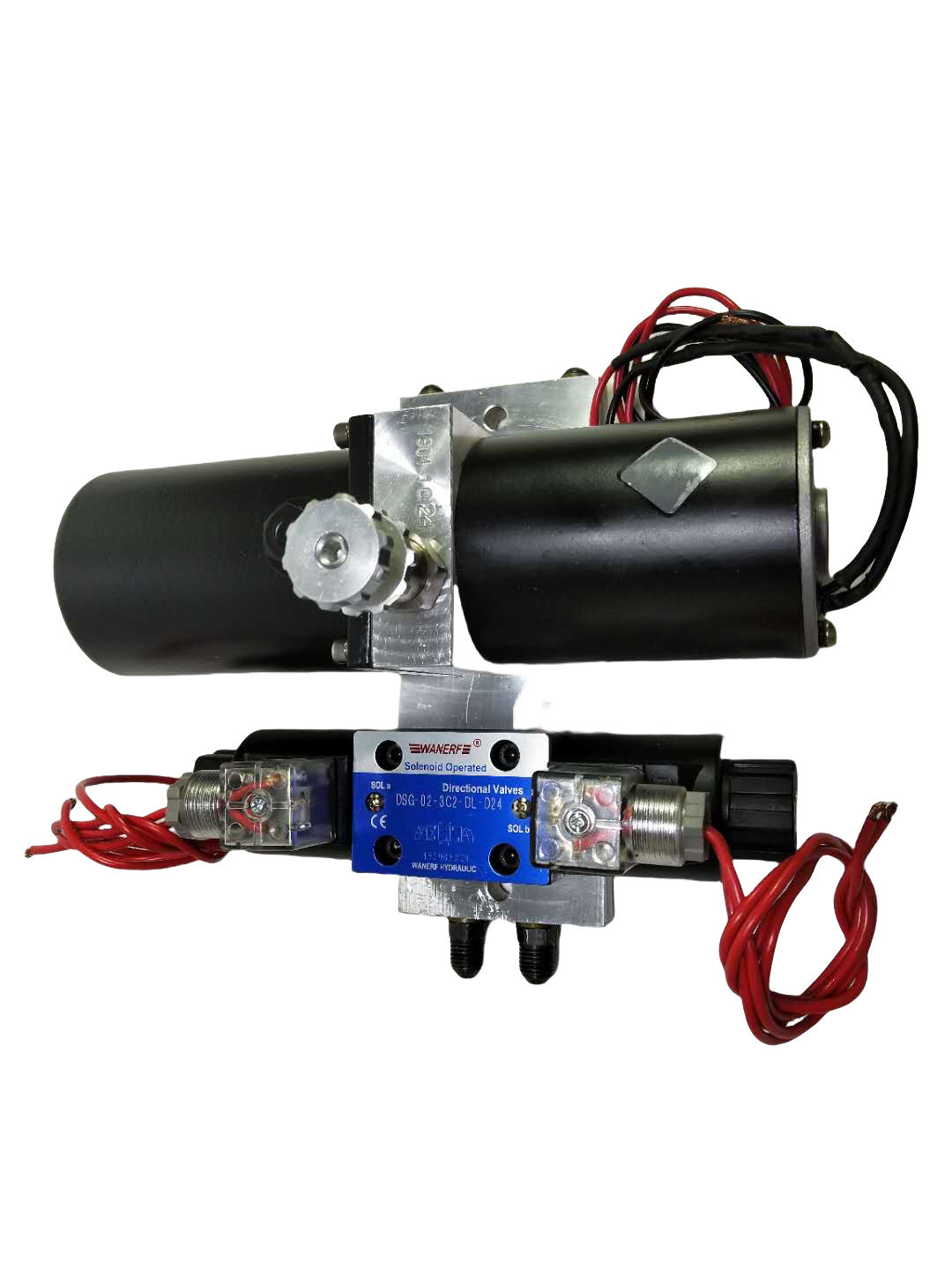

Double Acting DC Hydraulic Power Unit with Solenoid Directional Valve

Product Struction

Key Features & Advantages

1. Designed for Double Acting Cylinders

Pressurized extension and retraction, ideal for applications requiring strong and accurate bidirectional control.

2. Integrated 4/3 Solenoid Directional Valve

Ensures fast switching, low leakage, and stable motion at any load. Available in 12V or 24V configurations.

3. Compact All-in-One Structure

Pump, motor, reservoir, valve—and manifold block integrated into one compact unit, minimizing installation space.

4. High-Efficiency DC Motor

Powerful and durable, delivering consistent performance in both intermittent and continuous duty cycles.

5. Precision Gear Pump

Provides high volumetric efficiency, low noise, and long service life.

6. Multiple Mounting & Porting Options

Designed to fit a variety of machinery layouts and custom hydraulic circuits.

7. OEM / ODM Customization

We customize ports, valve types, pump displacement, voltage, wiring connectors, mounting flanges, and even full hydraulic circuit design.

Typical Applications

This power unit is widely used in hydraulic systems requiring controlled extension and retraction:

-

Marine steering gear systems

-

Tailgate lifts & utility trailers

-

Garbage truck compression systems

-

Off-road vehicles & ATV/UTV attachments

-

Agricultural machinery

-

Compact industrial automation

-

Material handling equipment

-

Small construction machines and cylinders

Wherever a double acting cylinder is used, this power unit delivers reliable motion control.

Technical Specifications

(Values can be adjusted to your exact model; this表格你可直接用于页面)

| Item | Specification |

|---|---|

| System Type | Double Acting, DC Hydraulic Power Unit |

| Voltage Options | 12V / 24V DC |

| Motor Power | 0.8–2.2 kW (customizable) |

| Gear Pump Displacement | 0.8–4.0 ml/r (optional ranges available) |

| Rated Pressure | 160–200 bar |

| Max Pressure | 220–250 bar |

| Directional Valve Type | 4/3 Solenoid Valve (Center Closed / Center Open optional) |

| Flow Rate | 3–12 L/min |

| Oil Port | A / B working ports + T return port |

| Tank Material | Steel or aluminum |

| Tank Capacity | 1–4 L (custom available) |

| Duty Cycle | S3 intermittent |

| Noise Level | ≤ 75 dB |

| Protection | IP54 / IP65 for solenoid coils |

Final specifications can be matched to your cylinder size, working load, and cycle time.

How It Works

-

Motor drives the gear pump to generate hydraulic flow.

-

The solenoid directional valve routes oil to the A or B port.

-

Cylinder extends or retracts based on valve position.

-

In neutral (center) position, flow stops or returns to tank depending on valve configuration.

-

System maintains pressure with optional relief valve settings.

This ensures precise, smooth, and safe operation under various load conditions.

OEM / ODM Customization Options

We support full customization to match your hydraulic system:

-

Customized hydraulic schematics

-

Special mounting plates & hole patterns

-

Wiring connectors, Deutsch plugs

-

Tank size & shape

-

Valve types: 4/3, 4/2, manual emergency valve

-

Relief valve pressure settings

-

Pump displacement & flow rate

-

Color, branding, private label

Our engineers can design the entire hydraulic solution based on your cylinder size and force requirements.

Quality Assurance

Every power unit is tested before shipment:

-

Pressure test at rated load

-

Leakage inspection

-

Valve switching performance test

-

Electrical coil endurance test

-

Noise & vibration evaluation

-

100% functional test of A/B port switching

We guarantee consistent performance across all production batches.

FAQ – For Serious Buyers

Q1: Can this power unit operate any double acting cylinder?

Yes, as long as cylinder bore and flow demand match the pump displacement and pressure rating. Our team can help you select the correct configuration.

Q2: Can you customize the hydraulic circuit?

Absolutely. We design and manufacture complete customized valves, manifolds, and control systems.

Q3: What information do you need for a quote?

-

Voltage (12/24V)

-

Cylinder bore & stroke

-

Load weight or required force

-

Expected duty cycle

-

Mounting direction

-

Any desired valve functions

Q4: Do you provide sample units?

Yes. Prototype samples are available.

Request a Quote

Tell us your application and hydraulic requirements, and our engineering team will recommend the correct configuration and send your quotation within 24 hours.

✔ Voltage (12V / 24V)

✔ Cylinder size (bore & stroke)

✔ Load & working pressure

✔ Duty cycle

✔ Port and mounting requirements

✔ Any drawings or photos of your current system

Contact us now to get a technical proposal and pricing.