Hydraulic power packs are essential components in many industrial applications, providing the power necessary for various hydraulic systems. In this article, we’ll explore the working principles of hydraulic power pack circuits, their components, and their role in industrial machinery. We’ll also dive into some common types of hydraulic circuits and their specific applications.

Table of Contents

- Introduction to Hydraulic Power Packs

- Components of Hydraulic Power Pack Circuits

- Working Principle of Hydraulic Power Packs

- Hydraulic Power Pack Circuit Design

- Types of Hydraulic Power Pack Circuits

- Applications of Hydraulic Power Packs

Introduction to Hydraulic Power Packs

Hydraulic power packs are systems that provide hydraulic power to machines or devices. These systems convert mechanical energy into hydraulic energy, driving hydraulic cylinders, motors, or other actuators. They are used in a wide range of industries, including manufacturing, construction, and automotive sectors.

Components of Hydraulic Power Pack Circuits

The hydraulic power pack circuit is made up of several critical components, each playing a vital role in the system's operation. These include:

- Hydraulic Pump: The heart of the power pack, the hydraulic pump converts mechanical energy into hydraulic energy by circulating oil under pressure.

- Hydraulic Reservoir: The reservoir holds the hydraulic fluid, ensuring that the system has an adequate supply of fluid for circulation.

- Control Valves: These valves regulate the flow and pressure of the hydraulic fluid, directing it to various parts of the circuit based on the system's needs.

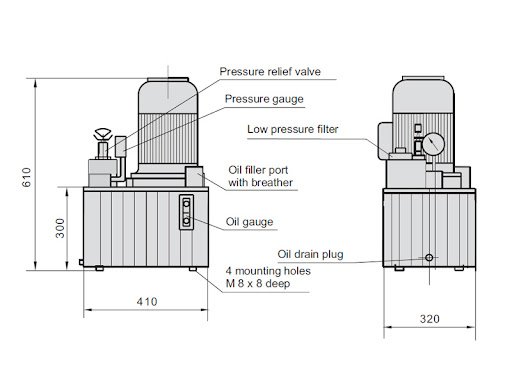

- Pressure Relief Valve: This safety device ensures that the system doesn't exceed safe pressure limits by diverting excess pressure.

- Hydraulic Cylinders and Motors: These actuators use hydraulic energy to perform mechanical work, such as lifting, moving, or rotating parts.

Working Principle of Hydraulic Power Packs

The working principle of a hydraulic power pack involves the conversion of energy from an electric motor to hydraulic fluid under high pressure. The hydraulic pump powered by the motor moves fluid from the reservoir and sends it through the system. The fluid flows through the control valves, which regulate the direction, pressure, and flow rate. Depending on the circuit design, the fluid activates hydraulic actuators to perform various tasks.

The pump’s role is crucial as it creates the pressure required to perform the necessary mechanical work, while the reservoir provides a continuous supply of fluid to maintain the system’s operation.

Hydraulic Power Pack Circuit Design

Designing a hydraulic power pack circuit involves several considerations, including the type of hydraulic system, the required pressure, and the overall performance needed. The circuit design typically includes the selection of the pump type (gear, vane, or piston), control valves, and pressure regulators to ensure optimal operation.

| Component | Description | Function |

|---|---|---|

| Hydraulic Pump | Converts mechanical energy to hydraulic energy | Drives the fluid circulation |

| Control Valves | Directs hydraulic fluid flow to specific parts of the system | Controls the direction and speed of actuators |

| Pressure Relief Valve | Limits system pressure to safe levels | Prevents pressure overload |

Types of Hydraulic Power Pack Circuits

There are different types of hydraulic circuits used in power packs, each suited to specific tasks and performance requirements. Below are some of the common types:

- Open-Loop Circuit: In this circuit, the hydraulic fluid is pumped from the reservoir, passes through the system, and then returns directly to the reservoir. It is simpler and used for low-power applications.

- Closed-Loop Circuit: A more complex system where the hydraulic fluid is continually recirculated through the pump, ensuring consistent pressure and reducing energy loss. It is typically used for high-performance applications.

- Single-Acting Circuit: In this circuit, hydraulic fluid is used to move the actuator in one direction, and a spring or gravity returns it to the starting position.

Applications of Hydraulic Power Packs

Hydraulic power packs are widely used across many industries. Some of the key applications include:

- Manufacturing: Used to drive machines such as presses, injection molding machines, and other industrial equipment.

- Construction: Powers heavy equipment like excavators, loaders, and bulldozers.

- Automotive: Used in automotive assembly lines, lifting equipment, and hydraulic jacks.

- Aerospace: In aircraft, hydraulic power packs drive the flight control systems and landing gear mechanisms.

Hydraulic power pack circuits provide reliable and efficient power solutions across these industries, ensuring that tasks are completed with precision and safety.